Fabrisonic Heat Exchangers Meets Stringent NASA JPL TRL 6 Qualifications

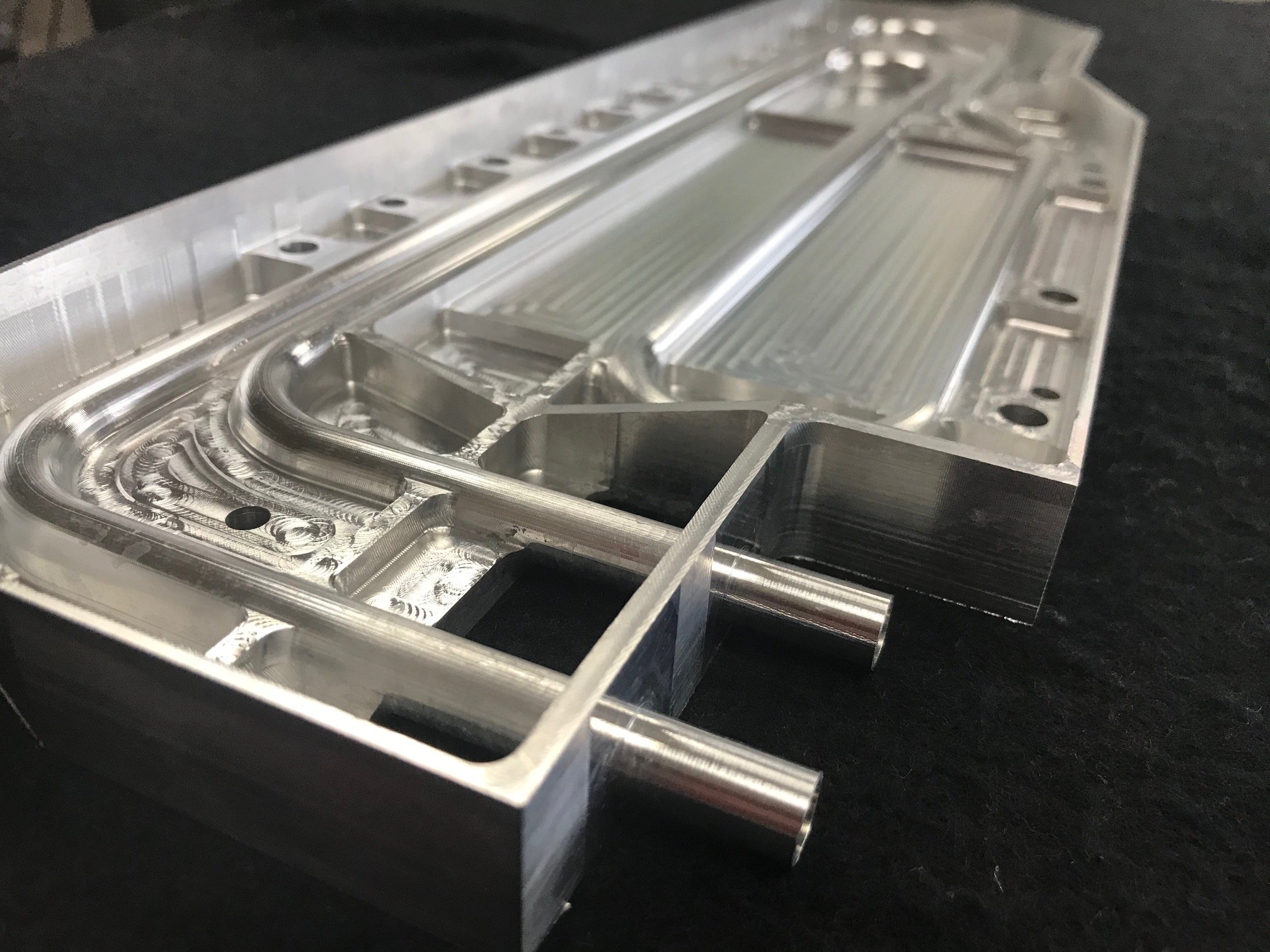

Fabrisonic's patented metal 3D printing process, Ultrasonic Additive Manufacturing (UAM), enables joining alloys that have historically been difficult to weld. Examples include 1000, 2000, 6000, and 7000 series aluminums, coppers, stainless steels, and exotic refractory metals, all commonly used in NASA's Jet Propulsion Laboratory (JPL) heat management systems.

Justin Wenning, Production Engineer at Fabrisonic, recently wrote 'Space-grade 3D Metal Printed Heat Exchangers', which delves deeper into the fundamental work he is doing at Fabrisonic in the heat exchanger space.